In modern organizations, efficiency and consistency are essential for sustainable success. As businesses expand and operations become more complex, relying on informal practices or individual experience is no longer sufficient. This is where the Protocolo Operacional Padrão (POP) becomes a critical management tool. POPs establish efficient process standards that guide employees, reduce operational risks, and ensure that tasks are performed correctly and uniformly. Far from being simple procedural documents, POPs are strategic assets that support productivity, quality, and organizational growth.

Understanding Protocolo Operacional Padrão

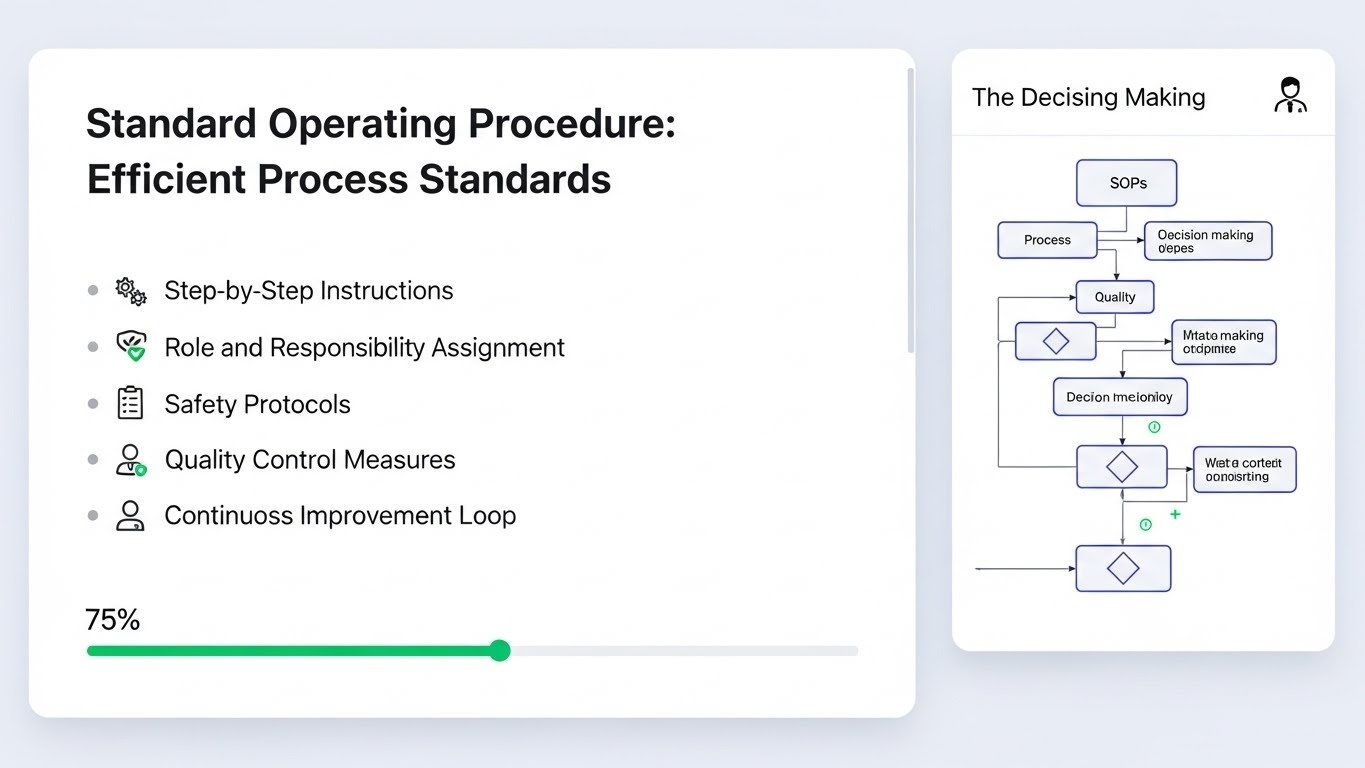

A Protocolo Operacional Padrão is a documented set of standardized instructions that describe how specific tasks or processes should be executed. These instructions outline the sequence of actions, responsible roles, required tools, and expected outcomes. The primary purpose of a POP is to ensure that processes are carried out consistently, regardless of who performs them.

POPs are widely applied across industries such as healthcare, manufacturing, food services, logistics, education, and corporate administration. In all these contexts, the core principle remains the same: transforming knowledge into repeatable, reliable processes that support efficiency and quality.

The Importance of Efficient Process Standards

Efficient process standards are essential for maintaining operational control. Without standardization, organizations face inconsistent results, increased errors, and inefficiencies that affect performance and customer satisfaction. POPs provide a clear operational framework that aligns daily activities with organizational goals.

By defining best practices, POPs reduce uncertainty and variation in task execution. Employees can focus on performing their duties effectively rather than figuring out how to complete tasks. This clarity improves workflow, strengthens accountability, and creates a more organized work environment.

Key Elements of an Effective POP

An effective POP is well-structured, easy to understand, and practical to use. Although formats may vary, most POPs include the following components:

Clear Title and Purpose

The title identifies the process, while the purpose explains why the POP exists and what it aims to achieve.

Scope and Application

This section defines where and when the POP should be applied, ensuring it is used appropriately across departments or roles.

Roles and Responsibilities

Clearly assigned responsibilities prevent confusion and ensure accountability at every stage of the process.

Required Resources

Listing tools, materials, or systems needed for the process helps employees prepare and avoid interruptions.

Step-by-Step Procedures

The procedure section provides a logical sequence of actions, written in simple and direct language to minimize errors.

Quality and Safety Guidelines

Quality checks and safety measures help maintain standards and reduce operational risks.

Review and Revision Details

Including review dates and version control ensures the POP remains current and effective over time.

Benefits of Implementing POPs

Increased Operational Efficiency

Standardized procedures reduce wasted time and effort by eliminating ambiguity. Tasks are completed faster and more accurately when employees follow clear guidelines.

Consistency and Quality Assurance

POPs ensure that outputs meet the same standards every time. This consistency strengthens trust among customers, partners, and stakeholders.

Reduced Errors and Risks

Clear instructions and checkpoints minimize mistakes, accidents, and non-compliance with regulations.

Improved Training and Onboarding

New employees can quickly understand their roles through POPs, reducing training time and dependency on informal instruction.

Knowledge Retention

POPs capture organizational knowledge, protecting businesses from disruptions caused by employee turnover.

POPs in Different Organizational Contexts

Manufacturing and Production

In manufacturing environments, POPs define machine operation, maintenance routines, and quality control procedures. This results in safer workplaces, fewer defects, and improved productivity.

Healthcare and Medical Services

Healthcare organizations rely heavily on POPs to ensure patient safety, hygiene, accurate documentation, and standardized care practices.

Food and Hospitality

POPs in food services help maintain hygiene standards, consistent recipes, and service quality while ensuring compliance with health regulations.

Office and Administrative Operations

Administrative POPs support tasks such as financial reporting, customer service, data management, and internal communication, ensuring accuracy and efficiency.

How POPs Support Organizational Growth

As organizations grow, processes must scale without losing quality or control. POPs enable scalability by providing repeatable systems that can be applied across teams, locations, or franchises. New employees and units can quickly align with established standards, ensuring uniform performance.

POPs also improve decision-making by offering measurable benchmarks. Managers can assess performance, identify bottlenecks, and implement improvements based on documented processes.

Developing Effective POPs

Creating an effective POP requires collaboration, clarity, and continuous improvement. The development process typically includes the following steps:

-

Identify Critical Processes

Focus on tasks that are repetitive, high-risk, or essential to operational success. -

Engage Subject Matter Experts

Employees who perform the tasks regularly provide practical insights and help ensure accuracy. -

Document Clearly and Simply

Use clear language and logical structure to make the POP easy to understand and follow. -

Test the Procedure

Validate the POP in real working conditions and refine it based on feedback. -

Train Employees

Ensure staff understand both the content and the importance of following the POP. -

Review and Update Regularly

Processes evolve, and POPs must be updated to remain relevant and effective.

Overcoming Common Challenges

Resistance to Standardization

Some employees may perceive POPs as limiting flexibility. Involving them in development and emphasizing benefits can reduce resistance.

Outdated Documentation

Without regular reviews, POPs can become obsolete. Assigning ownership and review schedules helps maintain accuracy.

Over-Complexity

Excessive detail can overwhelm users. POPs should balance thoroughness with simplicity.

Digital POPs and Modern Workplaces

Digital transformation has significantly enhanced how POPs are created and managed. Digital POPs offer real-time updates, easy access, and version control. Employees can consult procedures on computers or mobile devices, improving adherence and efficiency.

Additionally, digital platforms allow organizations to track compliance, analyze performance data, and identify areas for improvement. This integration strengthens operational oversight and continuous improvement efforts.

POPs and Quality Management Systems

POPs play a vital role in quality management frameworks such as ISO standards. They provide documented evidence that processes are controlled, repeatable, and aligned with quality objectives. This strengthens internal discipline and enhances credibility with auditors, clients, and regulators.

Conclusion

The Protocolo Operacional Padrão is a cornerstone of efficient process standards in modern organizations. By standardizing how tasks are performed, POPs improve efficiency, ensure consistency, and reduce operational risks. They transform individual knowledge into organizational capability, enabling businesses to grow, adapt, and compete effectively.

Organizations that invest in well-designed POPs create a strong foundation for operational excellence. In an environment where efficiency and reliability define success, POPs remain an indispensable tool for building structured, resilient, and high-performing operations.